Bull Splitting Bandsaw for High Throughput Beef Processing

Posted by Warren Leamy on 14th Feb 2026

Splitting Bandsaw with Auto Blade Tensioning for High Throughput Beef Processing

A bull splitting bandsaw is one of the most important machines in any modern abattoir. In high throughput beef processing environments, production speed, cutting precision, blade life, and operator safety directly impact profitability.

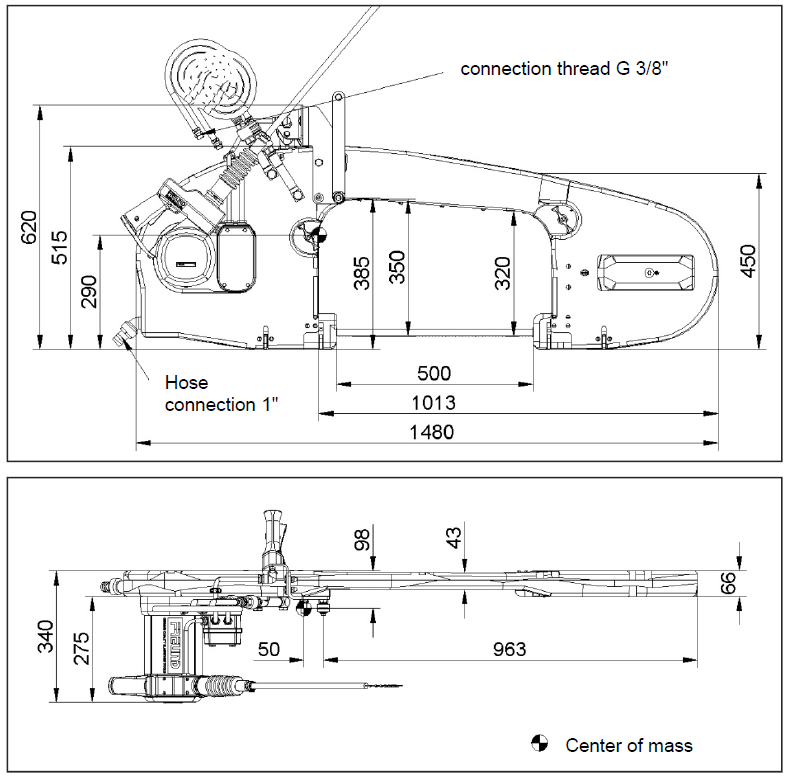

The 500mm Bull Splitting Bandsaw with Auto Blade Tensioning and Automatic Blade Twist Installation is engineered to deliver maximum throughput, minimal downtime, and optimal blade performance. Designed for heavy-duty Australian meat processing facilities, this industrial bull splitting bandsaw is built to be one of the fastest and most efficient systems available.

View the full specifications of the Bull Splitting Bandsaw with Auto Tensioning Blade System.

Why a 500mm Bull Splitting Bandsaw Is Critical for Large Carcass Processing

A 500mm cutting width provides the clearance required for:

-

Large beef carcasses

-

Mature bulls

-

Buffalo and camel processing

-

Export-grade beef operations

-

High-volume abattoirs

The wider cutting capacity allows operators to achieve a straight, accurate split without repositioning the carcass. This improves:

-

Processing speed

-

Workplace safety

-

Yield retention

-

Line efficiency

-

Overall plant productivity

For facilities scaling production, investing in a heavy-duty industrial meat bandsaw with 500mm clearance is essential.

Explore our complete range of commercial meat processing equipment to see how high-performance systems integrate into full processing lines.

Engineered for Speed: One of the Fastest Bull Splitting Bandsaws on the Market

In high throughput beef processing, speed must never compromise safety or accuracy.

This 500mm bull splitting bandsaw achieves superior performance through:

-

High-powered motor design

-

Rigid heavy-duty stainless steel frame

-

Precision blade tracking

-

Automatic hydraulic blade tensioning

-

Automatic blade twist installation

-

Blade change and tensioning in under 10 seconds

The ability to change and tension the blade in less than 10 seconds significantly reduces production stoppages — a major competitive advantage in continuous processing facilities.

The Result:

-

Faster carcass splitting

-

Reduced downtime

-

Improved shift-to-shift consistency

-

Lower reliance on highly skilled setup operators

For detailed performance specifications, visit the Bull Splitting Bandsaw product page.

Automatic Blade Tensioning: Maximising Blade Life & Cutting Precision

One of the most valuable features of this bull splitting bandsaw is its automatic hydraulic blade tensioning system.

How Automatic Tensioning Improves Performance

The system automatically applies and maintains optimal blade tension during operation. This ensures:

-

Consistent, straight carcass splits

-

Reduced blade deflection

-

Improved alignment accuracy

-

Reduced operator error

-

Extended blade lifespan

Incorrect tension is one of the leading causes of:

-

Blade breakage

-

Premature blade wear

-

Skew cutting

-

Motor overload and overheating

-

Inconsistent splitting

Automatic blade tensioning ensures the blade always operates within manufacturer-recommended specifications.

The hydraulic system can also be fine-tuned to suit local operating conditions, allowing slight tension adjustments to match blade type and tooth configuration for optimal cutting speed.

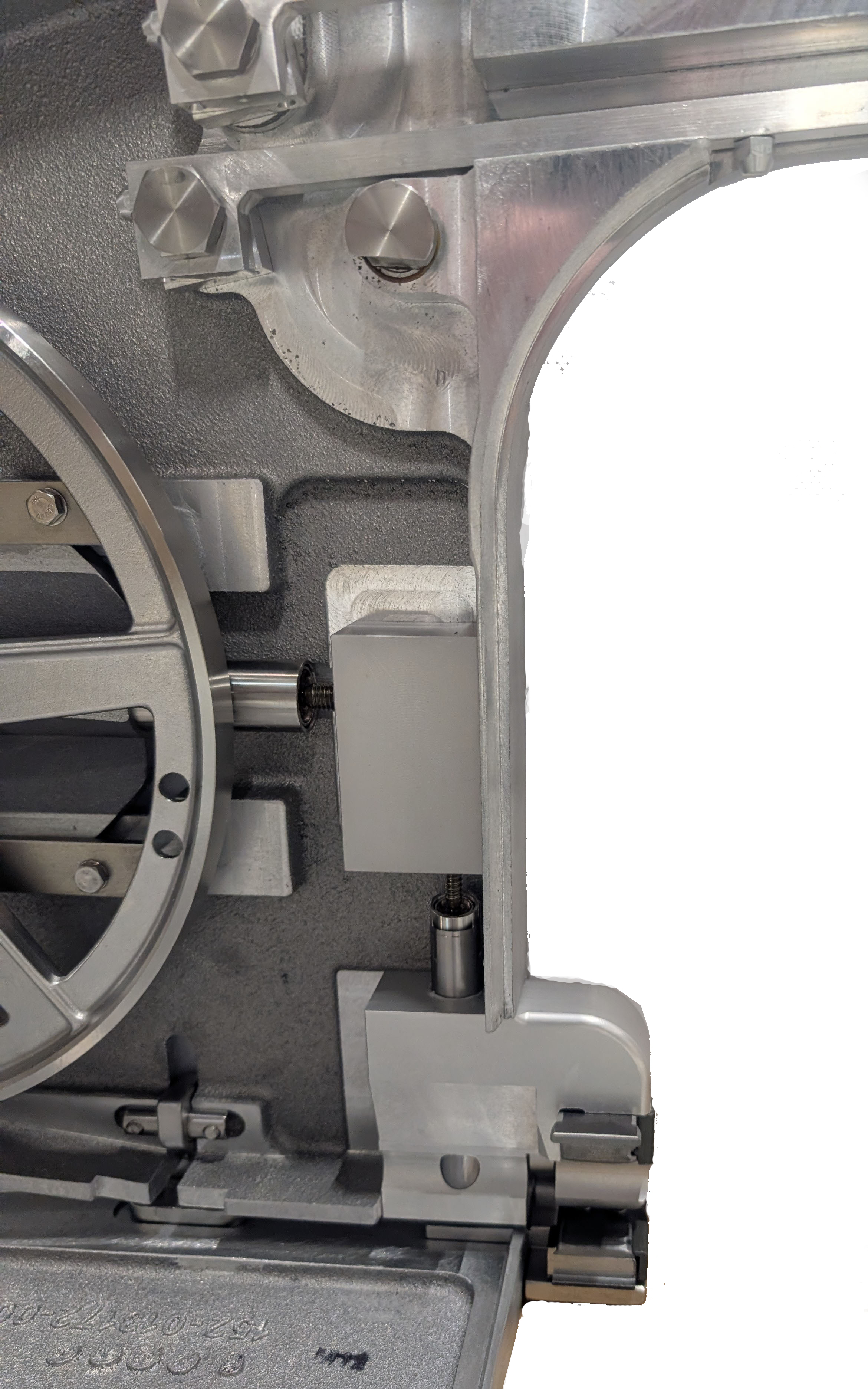

Immage below showing Auto blade tenstioning via hydraulic movement from the door closing, immage also shows the blate setting and twisting location via the same door closing movement

The Commercial Advantage

For plants processing hundreds of carcasses daily, extending blade life delivers:

-

Lower consumable costs

-

Reduced maintenance

-

Fewer unexpected stoppages

-

Higher throughput consistency

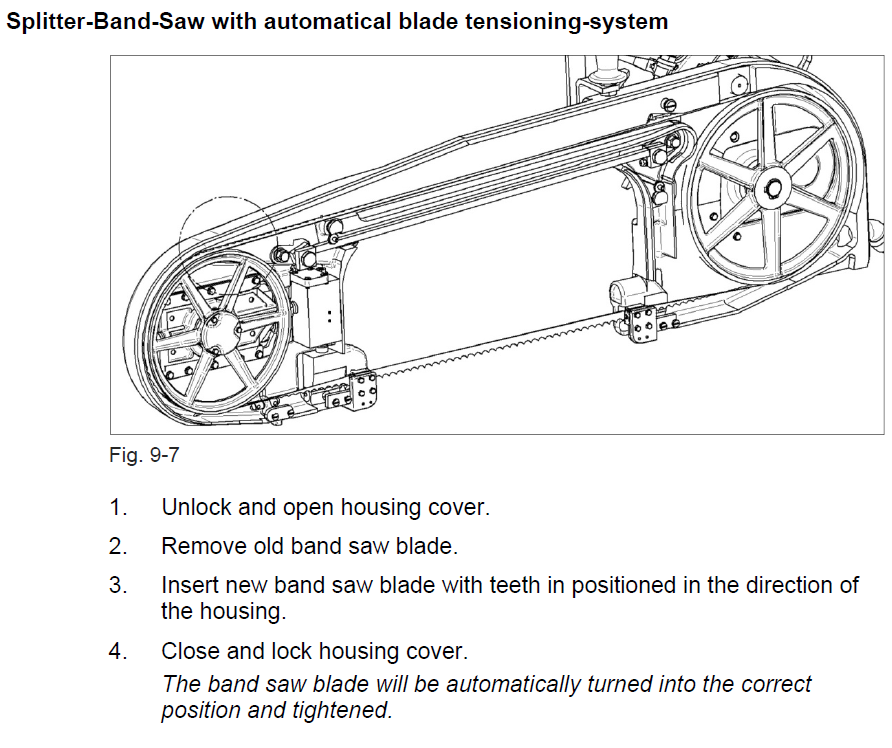

Automatic Blade Twist Installation: Faster, Safer Blade Changes

Traditional blade installation can be time-consuming and technically sensitive.

This bull splitting bandsaw features automatic blade twist technology, which:

-

Correctly orients the blade during installation

-

Eliminates setup errors

-

Speeds up changeovers

-

Minimises handling risks

In high throughput beef processing facilities, downtime equals lost revenue. Automatic blade twist installation ensures the blade is correctly positioned immediately, reducing restart delays and preventing costly mistakes.

Combined with automatic tensioning, this system makes blade replacement faster and safer than conventional industrial meat bandsaws.

Dual Hand Safety Controls & Magnetic Safety Covers

Performance must always be matched by safety.

This bull splitting bandsaw includes:

-

Dual hand safety controls

-

Emergency stop systems

-

Blade guards with magnetic safety switching

-

Washdown-safe control panels

-

Heavy-duty non-slip construction

Dual hand controls require both hands to activate the machine, ensuring operator hands are clear before cutting begins.

These safety measures align with guidance from Safe Work Australia (https://www.safeworkaustralia.gov.au/) and support compliance within regulated processing facilities.

Built for Australian Abattoirs

Australian beef processing facilities operate under strict hygiene and export standards, including frameworks supported by the Australian Meat Industry Council (AMIC) (https://www.amic.org.au/).

This bull splitting bandsaw is designed with:

-

Stainless steel construction

-

Corrosion resistance

-

Full washdown capability

-

Hygienic open-frame design

-

Heavy-duty industrial durability

When operating in high-volume environments, equipment must withstand continuous daily use while maintaining precision and safety.

MEFE supplies professional abattoir equipment solutions engineered for long-term reliability in Australian conditions.

Benefits of the 500mm Bull Splitting Bandsaw

Increased Processing Speed

-

Ultra-fast blade change (under 10 seconds)

-

Reduced downtime

-

Continuous high-speed operation

Extended Blade Life

-

Optimal hydraulic tension control

-

Reduced stress on blade and motor

-

Lower replacement frequency

Improved Splitting Accuracy

-

Straight carcass alignment

-

Reduced trimming loss

-

Protection of high-value primal cuts

Enhanced Workplace Safety

-

Dual hand activation

-

Magnetic safety covers

-

Reduced manual handling

Frequently Asked Questions

Is a 500mm bull splitting bandsaw necessary for all facilities?

No. Smaller processors may not require this cutting width. However, medium to large abattoirs benefit significantly from the added clearance and throughput efficiency.

Does automatic blade tensioning really extend blade life?

Yes. Maintaining consistent hydraulic tension prevents over-stressing the blade, reducing fatigue and extending usable life.

How fast can blades be changed?

With automatic blade twist installation and hydraulic tensioning, blades can be installed and tensioned in under 10 seconds.

Is this suitable for export facilities?

Yes. The stainless steel construction, hygiene-focused design, and safety features make it suitable for regulated processing environments.

Upgrade Your Bull Splitting Performance with MEFE

If your operation demands high throughput beef processing, reduced downtime, faster blade changes, and optimal blade life, the solution is clear.

View the 500mm Bull Splitting Bandsaw with Auto Blade Tensioning here:

https://www.mefe.com.au/bull-splitting-bandsaw-with-auto-tensioning-blade-2hatd

Or explore our full range of commercial meat processing equipment at:

https://www.mefe.com.au/

Invest in the fastest, most efficient bull splitting bandsaw available — and transform your processing line performance.