Steam Sucking Vacuum System SVSS

Steam Vacuum Sanitising

High-Efficiency Sanitising and Spot Cleaning for Abattoir Hygiene Compliance

The SVSS Steam Vacuum Sanitising System offers an advanced spot-cleaning solution for abattoirs and meat processing facilities. Widely adopted across Australia, the United States, and the European Union, SVSS systems use high-temperature steam to kill bacteria on animal carcasses, followed by high-powered vacuum extraction to remove dirt, ingesta, hair, and other contaminants—maximising hygiene while preserving carcass yield.

This system is engineered for the efficient removal of contamination and the reduction of microbial loads on slaughtered carcasses. It ensures improved food safety, reduced trimming waste, and enhanced product yield compared to traditional manual methods.

Applications & Compliance

Suitable for : Beef, Lamb, Pork, Goat Carcasses

Ideal Usage Points: Slaughter Floor, Boning Room, Chillers

Compliance Standards: Fully compliant with HACCP, USDA, AQIS, and EU hygiene regulations

Key Advantages

Targeted Vacuum Cleaning:

Efficient removal of visible contamination including soil, ingesta, and hair

Simultaneous Steam Disinfection:

High-temperature steam kills bacteria on contact

Superior Hygiene Results:

Significantly greater microbial reduction than knife trimming

Increased Food Safety:

Lower risk of cross-contamination via continuous steam disinfection

Yield Preservation:

Less product loss compared to manual trimming

No Surface Damage:

No visible alteration to carcass appearance

System Configuration

The SVSS can be customised to suit your processing line and operational requirements with the following components:

Vacuum Tank: Stainless steel, available in various capacities

Separator Can: Stainless steel design to prevent system clogging

Vacuum Pump: High-capacity rotary vane pump

Steam Generator: Provides consistent high-temperature output

Mobile Trolley & Brackets: For flexible floor use or fixed line integration

Ergonomic Handpieces: Optional attachments including fat scraper and spinal cord extractor

Modular Standard Component

Key Features

High-Temperature Sanitation

Steam output at 88°C to 94°C, eliminating bacteria on contact System generating up to 160 °C,

Instantaneous spot-cleaning without damaging carcass quality

Integrated Vacuum Extraction

High-velocity vacuum ensures rapid removal of loosened contaminants

No residual contamination left on carcass surfaces

Operator-Friendly Ergonomics

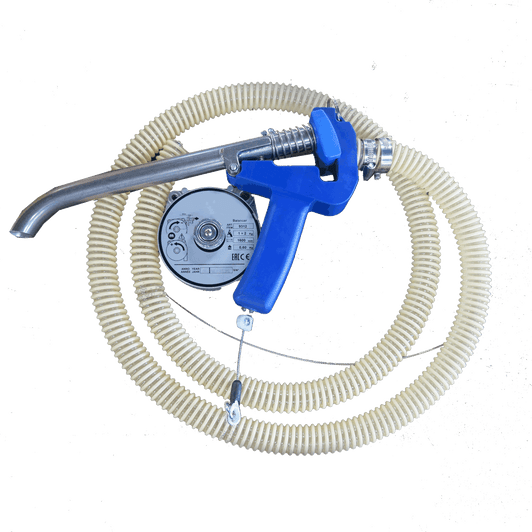

Lightweight sanitising wand with quick-release couplings for easy tool swaps

Optional accessories for spinal cord removal and fat scraping

Heavy-Duty Construction

Durable stainless steel tanks, fittings, and separators

Food-grade, thermally insulated hoses

Built for continuous operation in high-moisture environments

Flexible Setup Options

Mobile SVSS Trolley Unit for smaller floors or spot stations

Fixed Line SVSS System with mounted brackets for high-throughput lines

Technical Specifications ( Referring to standard inclusions)

| Feature |

Specification |

| Steam Generator |

15 KW 400V |

| Steam Temperature |

88°C–160°C adjustable |

| Steam Flow Rate |

28 Kg / Hour |

| Vacuum Flow Rate |

320-384 m³/h |

| Vacuum Pump |

4/4.6 kW Oil Free |

| Handpiece Weight |

Approx. 300g |

| Tank Capacity |

50–100L stainless steel waste tank |

| Hose Length |

4m standard Twin hose - Steam Vacuum |

| Power Supply |

415V 3-phase, 50Hz |

| Sanitisation Zone |

Targeted spot treatment: <50 cm² |

Performance Benefits

2–3 Log CFU/cm² reduction in microbial counts

Eradication visible contamination

Elimination non visible contamination

Fewer reworks and faster inspection approvals

Operator-safe design with cool handle and minimal scald risk

Enhanced processing efficiency aligned with HACCP workflows

Why Choose the SVSS?

Yield Preservation: Minimise trimming and product loss

Verified Compliance: Meets strict hygiene export standards

Operator Safety: Burn-free, ergonomic handpiece design

Flexible Modular Installation: Mobile or fixed setups to suit your facility speed and space

German - Australian Engineered: Built tough for continuous abattoir operation