Food Processing Glove Sizing Guide

Posted by MEFE on 8th Sep 2025

Proper food processing glove sizing prevents injuries, ensures compliance, and maintains productivity. Wrong-sized gloves cause contamination risks, reduced dexterity, and safety hazards in food processing environments.

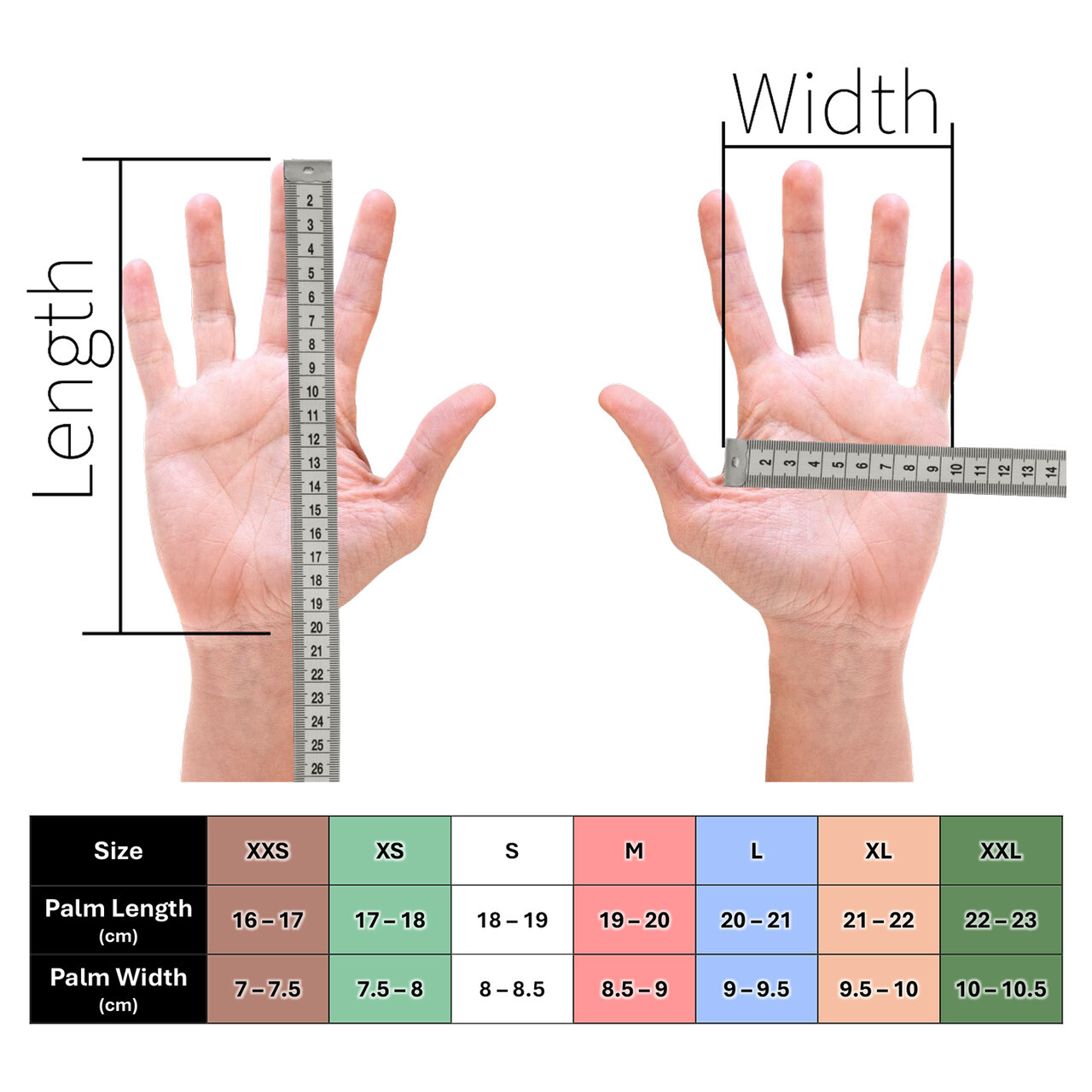

How to Measure Your Hand Size for Food Processing Gloves

Required Tools

- Fabric measuring tape

- Pen and paper

- Flat surface

Step-by-Step Measurement Process

Step 1: Hand Length (A)

- Place hand flat on surface

- Measure from base of palm to tip of middle finger

- Record measurement in centimeters

Step 2: Palm Width (B)

- Measure across widest part of palm

- Exclude thumb from measurement

- Record measurement in centimeters

Step 3: Size Selection

- Compare both measurements to size charts below

- Choose size that accommodates both measurements

- When between sizes, all MEFE Chainmesh gloves are supplied with a free glove tightener to help secure gloves that may be slightly loose.

For full wash-down or water-resistant setups, we recommend replacing the glove tightener with a Nitrile Disposable glove worn over the chain mesh.

This creates a hygienic seal and enables easy sanitisation during clean-downs — ideal for boning rooms, food prep zones, and HACCP-compliant workflows

MEFE Stainless Steel Chain Mesh Glove Size Chart

Sizing Guidelines by Product Type

Stainless Steel Chain Mesh - Full Hand

Key Sizing Requirements:

- Use measurements A and B from charts above

- Color-coded straps indicate size for easy identification

- Non-stretch stainless steel material - accurate sizing critical

Available Variants:

- Tiger Spring fastening system

- Panther Strap design

- Lion Claw configuration

Fit Check:

- ✅ Fingers move freely without restriction

- ✅ Palm coverage without gaps

- ✅ Wrist strap adjusts comfortably

Ultra Soft Cut Resistant Gloves

Key Features:

- FoodFlex material for enhanced comfort

- 5 color options available

- Superior dexterity for precision tasks

Sizing Considerations:

- Softer material allows slight stretch

- Focus on palm width for proper fit

- Ideal for extended wear applications

Stainless Steel Chain Mesh - Full Hand + 20cm Cuff

Additional Measurements Needed:

- Forearm circumference (15cm above wrist)

- Forearm length from wrist to elbow

Sizing Considerations:

- Cuff must not restrict blood flow

- Allow for clothing underneath

- Ensure full coverage during arm extension

Stainless Steel Chain Mesh - Full Arm with Harness

Complete Measurement Requirements:

- Hand size (standard method)

- Forearm circumference

- Upper arm circumference

- Shoulder width for harness fit

Critical Fit Points:

- Weight distribution across shoulders

- Unrestricted arm movement

- Secure harness without pressure points

Cotton Hypoallergenic Under-Gloves

Sizing Rule: Order one size smaller than your chain mesh gloves

Purpose:

- Moisture absorption

- Comfort enhancement

- Skin protection

- Hygienic barrier

Fit Requirements:

- Snug but not tight

- No bunching under outer gloves

- Easy donning and removal

Glove Tighteners and Straps

Standard Tighteners:

- One size fits most wrists (15-25cm circumference)

- Adjustable tension system

- Compatible with all chain mesh models

Metal Detectable Tighteners:

- Same sizing as standard

- Food safety compliance

- Enhanced contamination prevention

Replacement Straps:

- Match original glove model specifications

- Available for all chain mesh variants

- Easy field replacement

Nitrile Glove Seal (Wash-Down Alternative):

- For full wash-down or water-resistant setups, a Nitrile Disposable glove can be worn over the chain mesh glove in place of a strap or tightener

- Creates a hygienic seal for sanitisation and wet work

- Ideal for boning rooms, seafood processing, and HACCP-compliant workflow

Common Food Processing Glove Sizing Mistakes

Mistake 1: Too Tight

Problem: Reduced dexterity, hand fatigue, restricted blood flow

Solution: Size up and ensure 25mm fingertip clearance

Mistake 2: Too Loose

Problem: Contamination risk, reduced grip, safety hazards

Solution: Use glove tighteners or size down appropriately

Mistake 3: Ignoring Task Requirements

Problem: Wrong protection level for specific tasks

Solution: Match glove type and size to specific food processing activities

Mistake 4: Skipping Under-Gloves

Problem: Discomfort during extended wear

Solution: Add cotton hypoallergenic liners sized one size smaller

Quick Sizing Reference for Food Processing Tasks

|

Task Type |

Recommended Products |

Outcome |

|

General food prep |

Cut-resistant glove + nitrile overglove |

Dexterity for handling + hygienic moisture seal |

|

Meat cutting/deboning |

Cotton liner + chain mesh glove + glove tightener /nitrile overglove |

Cut protection + secure fit |

|

Heavy butchery |

Nitrile + cotton liner + full arm with harness (+ nitrile overglove) |

Maximum protection + weight distribution (+ liquid barrier) |

|

Extended shifts / Wet Environments |

Nitrile + cotton liner + chain mesh glove + nitrile glove overglove |

Comfort + secure fit + liquid protection |

Professional Fitting Tips

Before Purchasing:

- Measure both hands (use larger measurement)

- Consider typical work shift length

- Account for seasonal hand swelling

- Test with cotton liners if planning to use them

During Use:

- Check fit at start of each shift

- Adjust tighteners as needed

- Monitor for pressure points or restricted movement

- Replace when sizing becomes compromised

Signs of Proper Fit:

- Natural hand movement without restriction

- Secure positioning during work tasks

- Comfortable wear for full shift duration

- Adequate protection coverage for all exposed areas

Proper food processing glove sizing ensures worker safety, maintains food hygiene standards, and supports operational efficiency. For specific sizing consultation or product recommendations based on your facility's requirements, contact MEFE's protective equipment specialists.